MATERIALS SCIENCE AND CHEMISTRY

Molecular Dynamics Simulations of Deformation Processes in Nanostructured Metallic Glasses

Principal Investigator:

Karsten Albe

Affiliation:

Technische Universität Darmstadt

Local Project ID:

hda22

HPC Platform used:

JUQUEEN of JSC

Date published:

Metallic glasses are very strong and nonetheless elastic, making them appealing for diverse engineering applications. Despite these favourable properties, the failure of metallic glasses sets in directly after the elastic limit, making them brittle. In this project, scientists at the Technische Universität Darmstadt investigate nanostructured metallic glasses as a possible solution to this problem using large-scale molecular dynamics simulations.

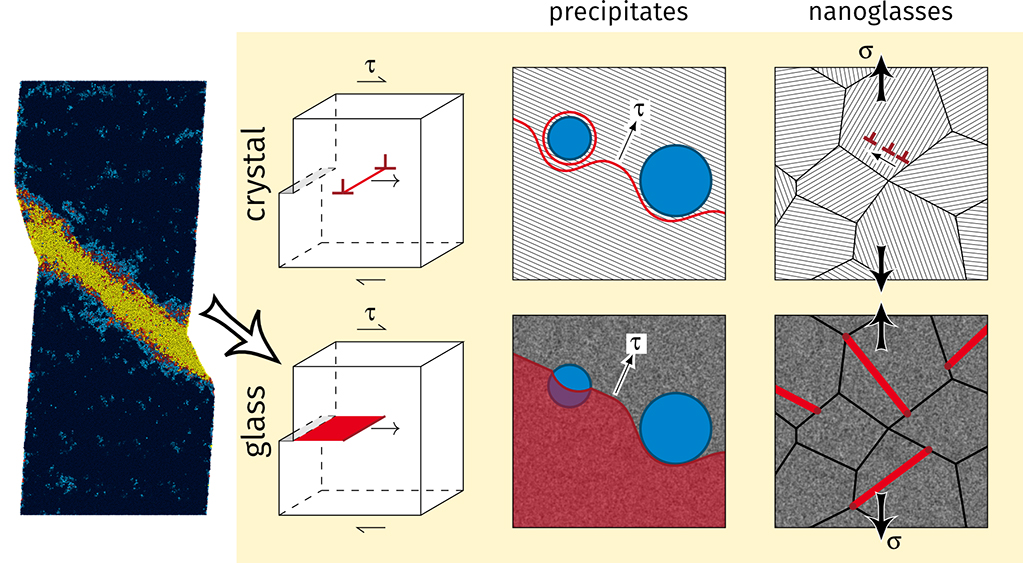

Metallic glasses are very strong and nonetheless elastic, making them appealing for diverse engineering applications. Despite these favourable properties, the failure of metallic glasses sets in directly after the elastic limit, making them brittle. Plastic deformation in these glasses is carried by so-called shear bands, which localise the deformation in very narrow regions which consequently fail quickly. To overvome this problem, one can take inspiration from crystalline materials: Here, precipitates hinder dislocation movement and grain boundaries serve as sinks and sources for them. While a shear band is not comparable to a dislocation, the solutions for tuning metallic glasses may look similar.

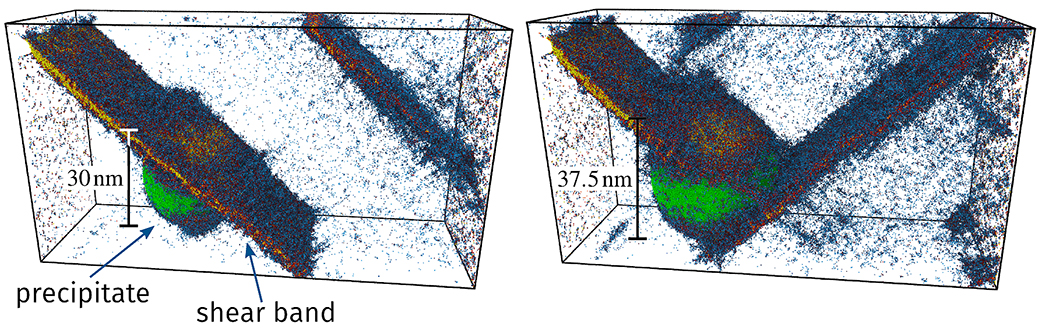

While these approaches have been tested experimentally, the microscopic mechanisms are not yet completely understood. To that end, scientists from the Technische Universität Darmstadt investigated the shear band propagation in nanostructured metallic glasses by molecular dynamics simulations on the JSC system JUQUEEN. Due to the length scales involved, system sizes up to 20 million atoms where needed; a perfect match for the high performance and parallelisation provided by JUQUEEN.

A first set of simulations was used to shed light on the interaction of an approaching shear band with crystalline precipitates and the influence of geometry. These crystal–glass composites are very attractive, as the crystalline volume fraction can be regulated by an annealing procedure. The simulations found that shear bands can wrap around smaller precipitates and continue unhindered. Only if a certain critical size is reached, the shear band will be blocked. Depending on the properties of the precipitate, it will either start deforming, or block the shear band indefinitely. It was possible to derive a mechanism map and a simple law to estimate the critical size [1].

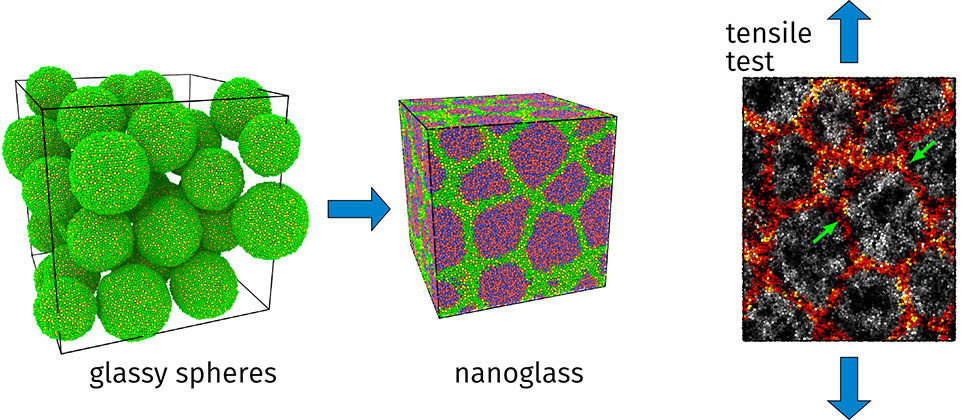

While the plasticity of the composite systems is limited, so-called nanoglasses offer a large plastic region even under tensile deformation. These materials are at first surprising: They have a microstructure comparable to nanocrystals. It is not immediately evident how “grain boundaries” in amorphous systems would look like. Experimentally, it was found that these glass–glass interfaces are characterized by a reduced density. The simulations on JUQUEEN reveal that this reduced density is accompanied by a changed composition. This can be explained by the synthesis: Amorphous nanoparticles—around 7 nm in diameter—are obtained by inert-gas condensation and cold-compacted to produce the nanoglass. Before compaction, though, surface segregation occurs, leading, for example, to a copper-rich layer for Cu-Zr-based nanoglasses [2].

Mechanical testing, such as the tensile test shown below, show that the deformation is mostly localised in the interfaces which distributes the strain more homogeneously over the sample. Critical shear bands can be avoided and significant plasticity achieved.

Acknowledgements:

This research is supported by DFG grants nos. AL 578/13-1 and AL 578/6-2, as well as within the subproject Nanoglasses of SPP 1594 (grant no. AL 578/15).

Publications:

[1] T. Brink, M. Peterlechner, H. Rösner, K. Albe, G. Wilde, Influence of crystalline nanoprecipitates on shear-band propagation in cu-zr-based metallic glasses, Phys. Rev. Applied 5 (2016) 054005. doi:10.1103/PhysRevApplied.5.054005.

[2] O. Adjaoud, K. Albe, Interfaces and interphases in nanoglasses: Surface segregation effects and their implications on structural properties, Acta Materialia 113 (2016) 284–292. doi:10.1016/j.actamat.2016.05.002.

[3] T. Brink, Heterogeneities in metallic glasses: Atomistic computer simulations on the structure and mechanical properties of copperzirconium alloys and composites, Ph.D. thesis, Technische Universität Darmstadt, Darmstadt (2016). URL tuprints.ulb.tu-darmstadt.de/5858

[4] C. Kalcher, T. Brink, J. Rohrer, A. Stukowski, K. Albe, Interface-controlled creep in metallic glass composites, Acta Materialia 141 (2017) 251 – 260. doi:10.1016/j.actamat.2017.08.058.

[5] O. Adjaoud, K. Albe, Microstructure formation of metallic nanoglasses: Insights from molecular dynamics simulations, Acta Materialia 145 (2018) 322–330. doi:10.1016/j.actamat.2017.12.014.

Scientific contact:

Karsten Albe

Technische Universität Darmstadt

FB 11, Material- und Geowissenschaften

Fachgebiet Materialmodellierung

Jovanka-Bontschits-Str. 2, L1|08| 211, D-64287 Darmstadt (Germany)

e-mail: albe [@] mm.tu-darmstadt.de