MATERIALS SCIENCE AND CHEMISTRY

Molecular Dynamics Simulations of Al-Mg-Alloys

Principal Investigator:

Martin Hummel

Affiliation:

Universität Stuttgart, Institut für Materialprüfung, Werkstoffkunde und Festigkeitslehre (IMWF)

Local Project ID:

MD-AlMg

HPC Platform used:

Hazel Hen of HLRS

Date published:

Aluminum alloys are widely used construction materials. A long tradition in metallurgy provides a lot of knowledge concerning the material behavior while different alloying surcharges are added or manufacturing processes are passed through. The strengthening in Aluminum-Magnesium alloys is based on different mechanisms, which are namely solid solution hardening, precipitate- and grain-boundary-strengthening. To investigate these empirical well-known effects on atomistic length scale Molecular Dynamics (MD) simulations are indispensable.

The interaction between each atom is considered in these numerical calculations and since the configurations consist of up to 900 million particles, the computational effort is very high. High performance facilities like the HLRS are the only possibility to provide the necessary infrastructure. Suitable simulation software is the other basic necessity, which is given in our case by the software package LAMMPS [1] .

Tensile tests are performed to observe the formation, evolution, movement and interactions of dislocations with each other, grain boundaries and other defects. A high-required stress for the dislocation formation was observed. This is a typical issue for MD-simulations and therefore it has to be clarified that the obtained results are realistic. Two main arguments always arise dealing with this topic. On the one hand, the high strain rates used in MD, since the possible simulated time is limited to µs, and on the other hand the size which has its upper limit somewhere at the µm regime. Accessing both limits in one simulation, by simulating a 1 µm aluminum cube for 1 µs, would take about 47,250 core years. Even for remarkable computational clusters like the Hazel Hen, it is not feasible on a regular basis, since this one simulation would use the whole system (185,088 computational cores) for three months.

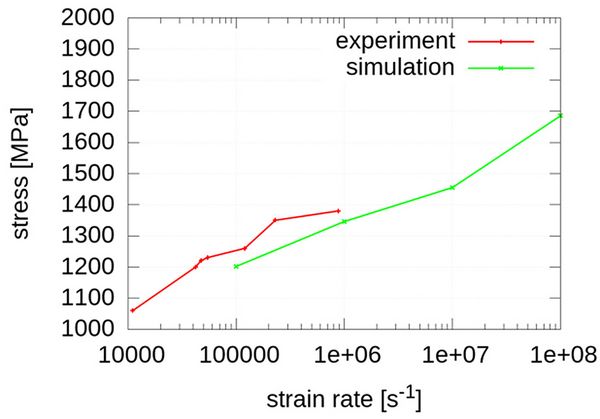

To overcome existing retentions, Figure 1 shows the smooth transition of experimental in red [2] and our simulated stress values in green. An ongoing decrease of maximum stress with decreased strain rate is observed. Still, it can be seen that the experimental values are in very good agreement and in smooth transition to the simulated results. Furthermore, the reduction of the maximum stress is only 40 % within 4 decades of strain rate reduction.

In order to deal with the argument of the size of the simulated specimen, the experimental investigation of the size effect by Wu et al. [3] has been used to connect experiment and simulation. The experimental results are presented in Table 1.

| Sample Size | Maximum stress [MPa] | Strain [%] | |

| mini | 1.5x0.5x0.5 mm³ | 60±3 | 0.1 |

| mico | 4.5±0.5x(2.0±0.2)² µm³ | 180±5 | 0.25 |

| nano | 400±100x200±50x150±50 nm³ | 750±10 | 1.0 |

Table 1: Experimental results of Wu et al. [3] of deformation experiments on [111]-oriented single crystal aluminum samples.

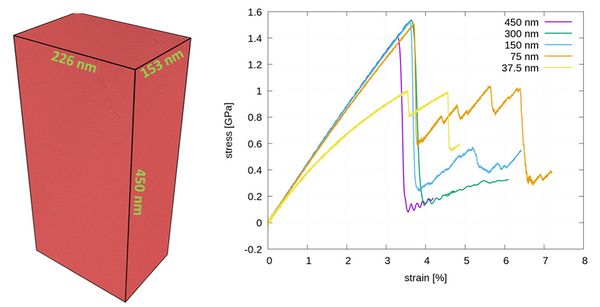

Figure 2 shows on the right hand side the stress strain curves of the simulated nano tensile test. The caption refers to the height of the system. The largest sample is shown on the left side of this picture, it is chosen at the size of the experimental nano sample. The second largest sample (green curve) is chosen at the lower limit of the experimental sample. It is seen, that the three samples with height from 75 – 300 nm show almost no influence on the maximum stress of 1505-1535 MPa, whereas the largest sample is leading to a decreased maximum stress of 1407 MPa, and therefore following the decreasing maximum stress with increasing size shown by the experiment. The smallest sample leads to a decreased maximum stress as well. This shows similarity to the transition of the regular to the inverse Hall-Petch effect. The factor of two in-between the experimental and simulated results is due to the difference of 10 orders of magnitude in the strain rate (Experiment 1x10-3 s‑1, simulation 1x107 s‑1).

This work was financially supported by the DFG SCHM746/154-1 and carried out at the IMWF (Institute for Materials Testing, Materials Science and Strength of Materials; www.imwf.uni-stuttgart.de).

References

[1] Sandia National Laboratories, LAMMPS Molecular Dynamics Simulator. [Online] Verfügbar unter: lammps.sandia.gov.

[2] G. I. Kanel, S. V. Razorenov, K. Baumung und J. Singer, „Dynamic yield and tensile strength of aluminum single crystals at temperatures up to the melting point“, Journal of Applied Physics, Jg. 90, Nr. 1, S. 136–143, 2001.

[3] J. H. Wu, W. Y. Tsai, J. C. Huang, C. H. Hsieh und G.-R. Huang, „Sample size and orientation effects of single crystal aluminum“, Materials Science and Engineering: A, Jg. 662, S. 296–302, 2016.

Scientific Contact

Martin Hummel

Universität Stuttgart

Institut für Materialprüfung, Werkstoffkunde und Festigkeitslehre (IMWF)

Pfaffenwaldring 32, D-70569 Stuttgart (Germany)

e-mail: martin.hummel [@] imwf.uni-stuttgart.de

HLRS project ID: MDAlMG

September 2019