MATERIALS SCIENCE AND CHEMISTRY

Influence of Velocity Changes During Directional Solidification Using Large-Scale Phase-Field Simulations

Principal Investigator:

Britta Nestler

Affiliation:

Karlsruhe Institute of Technology, Karlsruhe (Germany)

Local Project ID:

pace3d

HPC Platform used:

Hazel Hen (HLRS)

Date published:

Simulations have long been an integral part to supplement experiment and theory and became a powerful method to improve the understanding of physical phenomena. Leveraging the phase-field method - an established means for the investigation of the diffusion and phase-transformation-included microstructure evolution during solidification processes in 3D - materials scientists use high-performance computing to study representative volume elements resolving the multiphase microstructure which can be compared with experimental micrographs. Massive-parallel and highly optimized solvers are applied to increase the efficiencies of the simulations in the scientists' pursuit to investigate the directional solidification of binary and ternary eutectic reactions in large-scale domains.

Novel materials have changed our lives for thousands of years. Especially since the beginning of the industrial revolution, the development of new materials has become a driving force for innovations. The development of materials establishes the basis of our today's mobility, healthcare, security, energy supply, construction, and communication. New and improved materials offer a wide range of solutions for the future challenges in the fields of environmental protection, climate change, efficient use of resources, globalization, and communication.

Modern technical applications require high-performance materials with locally defined properties. For example, a turbine blade has to withstand increasing forces farther away from its rotation centre. Therefore, the material of the blade has to be elastic close to the centre of rotation to resist bending forces from vibrations and creep resistant at the outer part due to the higher velocities and therefore higher aerodynamic drag. These properties depend on the microstructure of the material being used. During directional solidification of eutectic alloys, various microstructures composed of rods and lamellae of different sizes, shapes and arrangements, evolve along the solidification direction. This results in long ranges of homogeneous microstructures with consistent properties. For example, the creep resistance improves for finer microstructures, whereas with a coarser microstructure, the elasticity increases.

The microstructure characteristics indispensably depend on the used material system and the applied process conditions. Especially the size of microstructure can be controlled by the externally applied solidification velocity. Therefore, the production of a blade with locally different properties would require a controlled change in the solidification velocity during the manufacturing process. With the development of such a blade, the weight of the turbine can be reduced and their performance range can be improved. Both design aspects lead to less consumption of fuel and hence to a reduction of CO2 emissions. Additionally, the operation costs can be diminished and the operational life time can be extended.

Despite the well-understood correlation between the evolving size of the microstructure and the solidification velocity [1], the adjustment processes in the microstructure during a velocity variation is topic of current research. Following [2-4], the microstructures refines as a reaction to acceleration of the solidification velocity with nucleation and splitting events of the rods and lamellae, whereas merging and overgrowing events dominate the coarsening process during decelerations. Full 3D samples of a material’s microstructure are required in order to investigate these complex three-dimensional adjustment processes,. For obtaining theses microstructures from experiments, a high technical effort like synchrotron tomography [5] is needed.

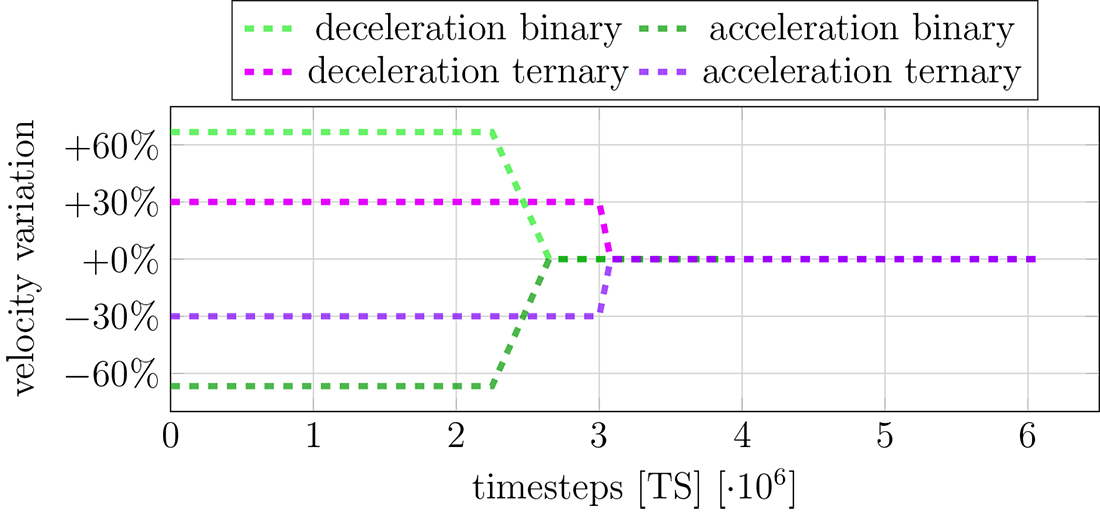

Fig. 01: Graphical overview of the growth velocities of simulations over simulation time steps.

Copyright: IAM, KIT (Germany)In the last decades, simulations have supplemented experiment and theory and became a powerful method to improve the understanding of physical phenomena. For the investigation of the diffusion and phase-transformation-included microstructure evolution during solidification processes in three dimensions, the phase-field method has been established [6]. To study representative volume elements resolving the multiphase microstructure which can be compared with experimental micrographs [7-9], large-scale domains are required. The usage of current high-performance computers is necessary to simulate such processes in large-scale domains with calculation-intensive models in a reasonable time. To increase the efficiencies of the simulations, massive-parallel and highly optimized solvers, like Pace3D [10, 11] and waLBerla [12, 13], are required. Using these optimized solvers on high-performance systems, the directional solidification of binary [7, 14, 15] and ternary eutectic reactions [2, 4, 9, 16-24] is investigated in large-scale domains. The computations are based on recent grand chemical potential formulations of a multicomponent phase-field approach [9, 25, 26].

This work gives an overview of the microstructure evolution of eutectic alloys during directional solidification containing velocity changes and is based on the works [2, 4, 14, 15].

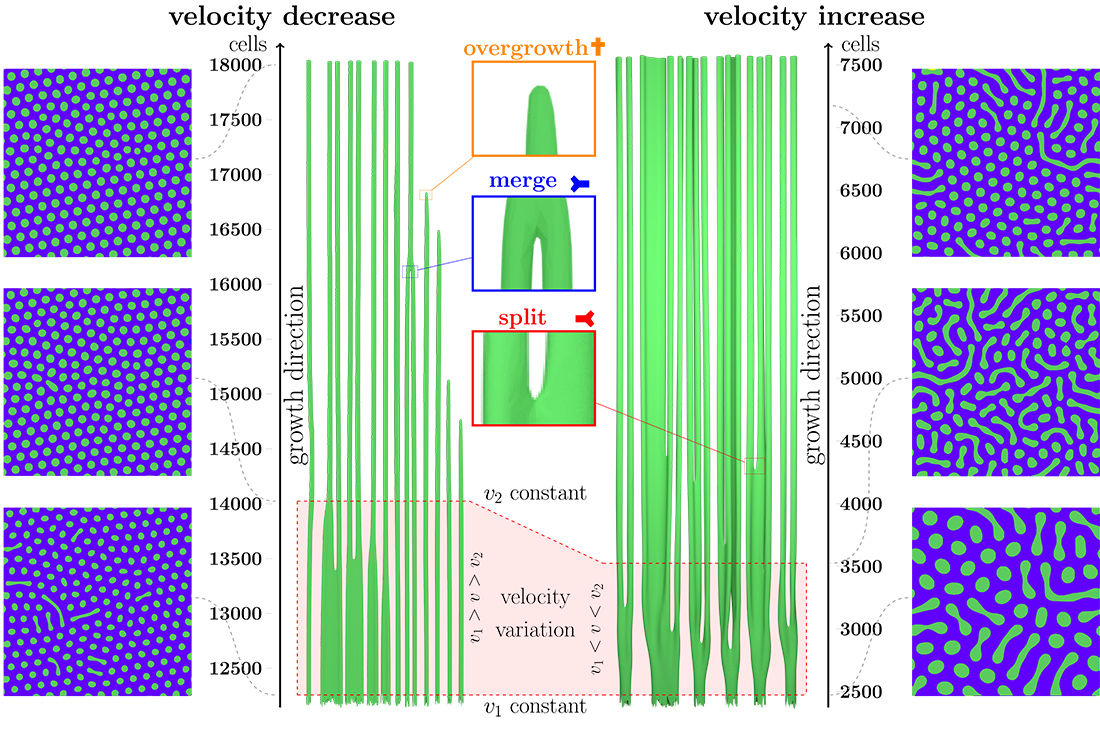

The solidification velocity profiles executed for the simulations of eutectic phase transformations in NiAl-34Cr and Ag-Al-Cu are schematically illustrated in fig. 1. A detailed description of the directional solidification of NiAl-34Cr during velocity variations can be found in [14, 15]. The growing pattern consists of Cr rich rods evolving in a NiAl matrix. Exempted rods containing a velocity decrease (left) and a velocity increase (right) are depicted in fig. 2. The extractions in the middle show representative examples for splitting, merging and overgrowing events by which the microstructure adjusts to the velocity changes. At both sides the microstructures before and after the velocity variation and at the end of the simulation are illustrated. According to the velocity-undercooling-spacing relationship [1], the rod diameters adjust. Independent from the kind of the velocity variation a better aligned arrangement of the rods is observed, at the end of both simulations. The simulations with a computational domain size of 600 x 600 voxel cells perpendicular to the growth direction are performed on 3,200 cores for 74 hours on the Hazel Hen supercomputer. Using a moving window technique, a final height of 8,000 voxel cells for the acceleration simulation and of 19,000 voxel cells for the deceleration simulation is reached. A detailed investigation of the solidification velocity, the resulting front undercooling, the rod spacings, their shape factors and the occurring events for single and multiple variations in the solidification velocity are given in [15]. To summarize the main conclusions, a deceleration of the velocity leads to a better aligned hexagonal arrangement and more rotund shape of the rods whereas an acceleration results in a mixture of both lamellae and rods.

Fig. 02: Computed micrographs perpendicular (left and right images) and parallel (central images) to the growth front of changing fiber arrangements due to different growth velocity variations. The various cross sections show selected rod arrangements with exemplary illustrations of microstructure adjustment events.

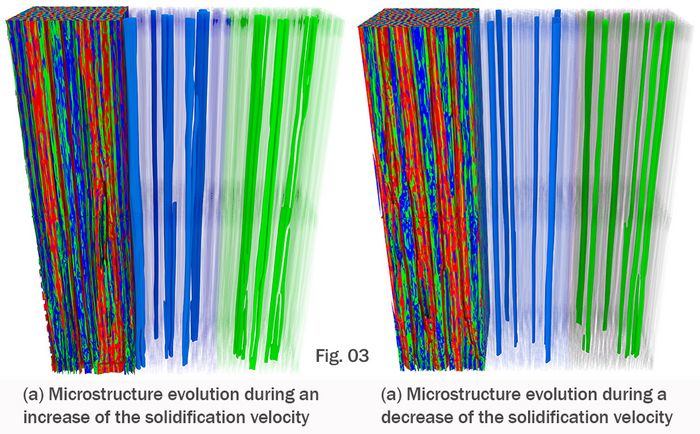

Copyright: IAM, KIT (Germany)In ternary eutectic alloys, more diverse patterns as in binary eutectic alloys evolve during directional solidification as described by geometrical considerations in [27] and by experiments in [28]. This leads to a more complex interaction between the process conditions and the evolving microstructure. In fig. 3, the influence of an acceleration (a) and deceleration (b) of the solidification velocity for the ternary eutectic system Ag-Al-Cu is depicted. The left parts of the images (a) and (b) display the entire microstructure capturing the initial state, the velocity change and the relaxation into adapted phase arrangements. Next to them, selected rods of the two intermetallic phases, Ag2Al (green) and Al2Cu (blue), are exempted. The simulations with a computational domain size of 800 x 800 x 275 voxel cells are calculated on 11,264 cores for approximately 40 h on the Hazel Hen supercomputer which resulted in a growth height of 14,672 voxel cells for the deceleration and 10,950 voxel cells for the acceleration simulation. As described in [2, 4], using a graph-based analysis approach, the microstructure refines during an acceleration by splitting of the rods and coarsens during a deceleration by overgrowing of rods. Thereby, mostly the intermetallic phases are involved in the adjustment process. Besides, the pattern remains stationary regarding morphological signatures under constant solidification velocity conditions.

Through the computational resources provided by the Hazel Hen system at the HLRS and highly optimized solvers, the influence of dynamic velocity variations could be investigated in representative three-dimensional domains for binary and ternary systems. These investigations increased the understanding of the rearrangement and adjustment processes in the microstructures required for the tailored development of materials with changing, locally defined microstructures.

Acknowledgments

The authors gratefully thank for the financial support within the project SKAMPY (Ultra-scalable multiphysics simulations for solidification processes in metals) founded by BMBF, the cooperative graduate school "Gefügeanalyse und Prozessbewertung" by the ministry of Baden-Wuerttemberg and the Helmholtz graduate school "Integrated Materials Development for Novel High Temperature Alloys".

Scientific Team:

Johannes Hötzer, Michael Kellner, Willfried Kunz, Britta Nestler (PI)

References:

[1] K. A. Jackson and J. D. Hunt. Lamellar and rod eutectic growth. Transactions of the Metallurgical Society of AIME, 236:1129-1142, 1966.

[2] J. Hötzer, P. Steinmetz, A. Dennstedt, A. Genau, M. Kellner, Irmak Sargin, and B. Nestler. Influence of growth velocity variations on the pattern formation during the directional solidification of ternary eutectic Al-Ag-Cu. 136:335-346, 2017.

[3] P. Steinmetz, J. Hötzer, A. Dennstedt, C. Serr, and B. Nestler. Investigation of three-dimensional microstructure rearrangement during ternary eutectic directional solidi cation of Al-Ag-Cu. Journal of Crystal Growth, page submitted, 2017.

[4] J. Hötzer. Massiv-parallele und großskalige Phasenfeldsimulationen zur Untersuchung der Mikrostrukturentwicklung. Ph.d. dissertation, Karlsruher Institut für Technologie (KIT), 2017.

[5] A. Dennstedt, L. Helfen, P. Steinmetz, B. Nestler, and L. Ratke. 3D Synchrotron Imaging of a Directionally Solidified Ternary Eutectic. Metallurgical and Materials Transactions A, pages 1-4, 2015.

[6] J. Hötzer, M. Kellner, P. Steinmetz, and Nestler B. Applications of the phase-field method for the solidification of microstructures in multicomponent systems. 96(3):235-256, 2016.

[7] M. Kellner, I. Sprenger, P. Steinmetz, J. Hötzer, B. Nestler, and M. Heilmaier. Phase-field simulation of the microstructure evolution in the eutectic NiAl-34Cr system. 128:379 - 387, 2017. ISSN 0927-0256. doi: dx.doi.org/10.1016/j.commatsci.2016.11.049. URL www.sciencedirect.com/science/article/pii/S0927025616306103.

[8] P. Steinmetz, Y. C Yabansu, J. Hötzer, M. Jainta, B. Nestler, and Surya R Kalidindi. Analytics for microstructure datasets produced by phase-field simulations. 103:192-203, 2016.

[9] J. Hötzer, M. Jainta, P. Steinmetz, B. Nestler, A. Dennstedt, A. Genau, M. Bauer, H. Köstler, and U. Rüde. Large scale phase-field simulations of directional ternary eutectic solidification. 93(0):194 - 204, 2015. ISSN 1359-6454. doi: 10.1016/j.actamat.2015.03.051. URL www.sciencedirect.com/science/article/pii/S135964541500227X.

[10] A. Vondrous, M. Selzer, J. Hötzer, and B. Nestler. Parallel computing for phase-field models. 28(1):61-72, 02 2014. ISSN 1094-3420. doi: 10.1177/1094342013490972. URL dx.doi.org/10.1177/1094342013490972.

[11] J. Hötzer, A. Reiter, H. Hierl, P. Steinmetz, M. Selzer, and B. Nestler. The parallel multi-physics phase-field framework pace3d. 2017 (submitted).

[12] C. Godenschwager, F. Schornbaum, M. Bauer, H. Köstler, and U. Rüde. A framework for hybrid parallel flow simulations with a trillion cells in complex geometries. In Proceedings of SC13: International Conference for High Performance Computing, Networking, Storage and Analysis, page 35. ACM, 2013.

[13] M. Bauer, J. Hötzer, M. Jainta, P. Steinmetz, M. Berghoff, F. Schornbaum, C. Godenschwager, H. Köstler, B. Nestler, and U. Rüde. Massively parallel phase-field simulations for ternary eutectic directional solidification. In Proceedings of the International Conference for High Performance Computing, Networking, Storage and Analysis, page 8. ACM, 2015.

[14] M. Kellner, J. Hötzer, P. Steinmetz, K. Dargahi Noubary, W. Kunz, and B. Nestler. Phase-field study of microstructure evolution in directionally solidified NiAl-34Cr during dynamic velocity changes. pages 372-375, 2017.

[15] M. Kellner, W. Kunz, P. Steinmetz, J. Hötzer, and B. Nestler. Phase-field study of dynamic velocity variations during directional solidification of eutectic NiAl-34Cr. 2017 (submitted).

[16] P. Steinmetz, M. Kellner, J. Hötzer, A. Dennstedt, and B. Nestler. Phase-field study of the pattern formation in Al-Ag-Cu under the influence of the melt concentration. 121:6-13, 2016.

[17] J. Hötzer, P. Steinmetz, M. Jainta, S. Schulz, M. Kellner, B. Nestler, A. Genau, A. Dennstedt, M. Bauer, H. Köstler, and U. Rüde. Phase-field simulations of spiral growth during directional ternary eutectic solidification. 106:249 - 259, 2016. ISSN 1359-6454. doi: dx.doi.org/10.1016/j.actamat.2015.12.052. URL www.sciencedirect.com/science/article/pii/S1359645415301580.

[18] K. Dargahi Noubary, M. Kellner, P. Steinmetz, J. Hötzer, and B. Nestler. Phase-field study on the effects of process and material parameters on the tilt angle during directional solidification of ternary eutectics. 138:403 -411, 2017. ISSN 0927-0256. doi: doi.org/10.1016/j.commatsci.2017.07.006. URL www.sciencedirect.com/science/article/pii/S0927025617303579.

[19] P. Steinmetz, J. Hötzer, M. Kellner, A. Dennstedt, and B. Nestler. Largescale phase-field simulations of ternary eutectic microstructure evolution. 117:205-214, 2016. doi: 10.1016/j.commatsci.2016.02.001.

[20] P. Steinmetz, M. Kellner, J. Hötzer, and B. Nestler. Quantitative comparison of ternary eutectic phase-field simulations with analytical 3D Jackson-Hunt approaches. 11 2017. ISSN 1543-1916. doi: 10.1007/s11663-017-1142-2. URL doi.org/10.1007/s11663-017-1142-2.

[21] P. Steinmetz. Simulation der bei der gerichteten Erstarrung ternärer Eutektika entstehenden Mikrostruktur mit der Phasenfeldmethode. Ph.d. dissertation, Karlsruher Institut für Technologie (KIT), Diss., 2017.

[22] J. Hötzer, M. Jainta, M. Ben Said, P. Steinmetz, M. Berghoff, and B. Nestler. High Performance Computing in Science and Engineering '15: Transactions of the High Performance Computing Center, Stuttgart (HLRS) 2015, chapter Application of Large-Scale Phase-Field Simulations in the Context of High-Performance Computing, pages 659-674. Springer International Publishing, 2016. ISBN 978-3-319-24633-8. doi: 10.1007/978-3-319-24633-8 42. URL dx.doi.org/10.1007/978-3-319-24633-8_42.

[23] J. Hötzer, M. Jainta, M. Bauer, P. Steinmetz, M. Kellner, H. Köstler, U. Rüde, and B. Nestler. High Performance Computing in Science und Engineering - Garching/Munich 2016 (2016), chapter Study of complex microstructure evolution in ternary eutectic alloys with massive parallel large-scale phase-field simulations. Bayerische Akademie der Wissenschaften, 2016. URL www.lrz.de/services/compute/supermuc/magazinesbooks/2016_SuperMUC-Results-Reports.pdf.

[24] J. Hötzer, M. Kellner, P. Steinmetz, J. Dietze, and B. Nestler. High Performance Computing in Science and Engineering '16: Transactions of the High Performance Computing Center, Stuttgart (HLRS) 2016, chapter Large-scale phase-field simulations of directional solidified ternary eutectics using high-performance computing. Springer International Publishing, 2017.

[25] A. Choudhury and B. Nestler. Grand-potential formulation for multicomponent phase transformations combined with thin-interface asymptotics of the double-obstacle potential. Physical Review E, 85(2):021602, 2012.

[26] M. Plapp. Unified derivation of phase-field models for alloy solidification from a grand-potential functional. Physical Review E, 84(3):031601, 2011.

[27] M. Ruggiero and J. Rutter. Origin of microstructure in the 332 K eutectic of the Bi-In-Sn system. Materials science and technology, 13(1):5-11, 1997.

[28] A. Dennstedt and L. Ratke. Microstructures of directionally solidified Al-Ag-Cu ternary eutectics. Transactions of the Indian Institute of Metals, 65 (6):777-782, 2012. ISSN 0972-2815. doi: 10.1007/s12666-012-0172-3. URL dx.doi.org/10.1007/s12666-012-0172-3.

Scientific Contact:

Dr.-Ing. Johannes Hötzer

Hochschule Karlsruhe - Technik und Wirtschaft, Institute of Materials and Processes

Karlsruher Institut für Technologie - Institut für Angewandte Materialien, Computational Materials Science (IAM-CMS)

Straße am Forum 7, D-76131 Karlsruhe (Germany)

E-Mail: johannes.hoetzer [@] kit.edu

http://www.imp.hs-karlsruhe.de/

http://www.iam.kit.edu/zbs/index.php

http://www.youtube.com/user/IMPKarlsruhe