MATERIALS SCIENCE AND CHEMISTRY

Large-Scale Phase-Field Simulations of Ternary Eutectic Directional Solidification

Principal Investigator:

Britta Nestler

Affiliation:

Institute of Applied Materials-Computational Materials Science, Karlsruhe Institute of Technology

Local Project ID:

TEDS

HPC Platform used:

Hornet and Hazel Hen of HLRS

Date published:

High performance materials with defined properties are crucial for the development and optimization of existing applications. Especially the possibility of exploiting the advantages of different materials are in focus of the research of high performance alloys as they are needed in applications with high mechanical and thermal requirements, e.g. in automobile, aerospace, and turbines.

The periodic table of elements includes 80 metallic elements which have the potential to form 82,160 different ternary alloys. From these, around 3,000 systems are partially investigated. For example, by adding different additive elements like Cr, Mo, W, C, Nb to unary or binary metallics, the creep resistance at high temperatures, the fracture toughness or the stiffness can be significantly improved.

Especially ternary eutectic alloys allow to study the underlying physical processes of microstructure evolution. During the solidification of these alloys at the ternary eutectic point, a melt transforms in three solid phases at a defined temperature and concentration. Ternary eutectic alloys offer a large variety of patterns and widely adjustable properties and build the basis for the understanding of multi-component systems. Due to the dependence of the mechanical properties from the underlying microstructure, the understanding of the physical mechanisms behind the pattern formation process and the influence of the different parameters is crucial.

To improve this understanding, the Karlsruhe Institute of Technology (KIT) and the University of Applied Science Karlsruhe (HSKA) collaborate closely with experimentalists from the German Aerospace Center (DLR) and the University of Alabama, Birmingham (UAB).

Due to the strong differences in the weights of the components, the ternary eutectic system Ag-Al-Cu is used for example to study the influence of gravity on the pattern formation process. To study the effects of gravity and the resulting convection, directional solidification experiments of Ag-Al-Cu are conducted on the international space station (ISS) by the end of 2015. High performance computing allows to study the pattern formation already without gravity, using simulations in which the process and material parameters can be specifically controlled.

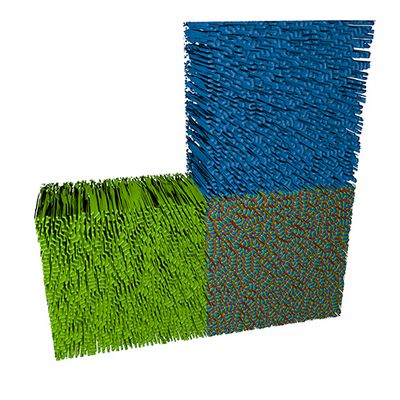

For the simulations, the researchers use a phase-field model based on the Grand potential approach [1] and thermodynamic Calphad databases [2] to investigate the directional solidification of the ternary eutectic system Ag-Al-Cu. This model leads to compute intensive partial differential equations to calculate the evolution of the microstructure. To study the formation of the patterns and their complex three dimensional interplay, large domains of more than 800 × 800 × 4000 voxel cells are required [3, 4]. In Fig. 1 the results of a simulation at the total Hornet supercomputer of HLRS (see Table 1) of the ternary eutectic system Ag-Al-Cu are depicted, forming so called brick-like structures. Videos of this simulation are available at:

https://www.youtube.com/watch?v=ZPKP87K1tt8

https://www.youtube.com/watch?v=tS1XBfpKK2s

Fig. 1: Pattern formation during the solidification of the system Ag-Al-Cu showing so-called brick-like structures. On the left in green and on the top in blue, the phases Ag2 Al and Al2 C u are exempted. Simulation details are summarized in Table 1 Hornet. © IAM-CMS, Karlsruhe Institute of Technology

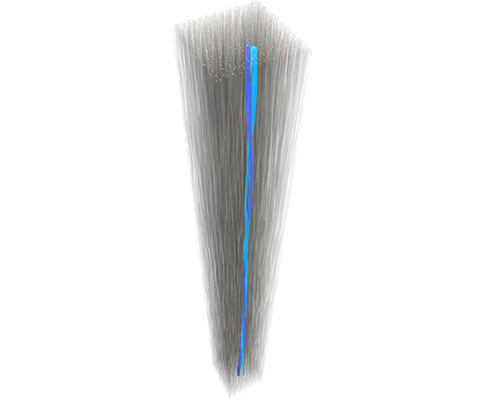

A special three-dimensional structure is helical spiral growth of two fibers, for which experimental evidence exists. To proof the occurrence of this pattern, high performance computing is employed to study large domain sizes which are necessary due to the complex interplay of the spirals with the neighbouring phases [5]. In Fig. 2, an example of spiral growth is depicted in a domain of 800 × 800 × 8520 voxel cells.

Fig. 2: Spiral growth during ternary eutectic directional solidification. In blue the two spiraling phases are highlighted in a transparent depicted microstructure. The simulation has a domain size of 800 × 800 × 8520 voxel cells and was calculated on the Hornet supercomputer at the HLRS Stuttgart using 13,600 cores. © IAM-CMS, Karlsruhe Institute of Technology

For simulating the computationally intensive model of combined diffusion and phase transition processes in large three-dimensional domains, the currently largest supercomputers are required. To efficiently exploit these supercomputers, the KIT/HSKA and the Universität Erlangen-Nürnberg (FAU) developed a highly optimized, specialized and parallel solver based on the waLBerla framework [6] (waLBerla framework). Particular buffering, classification techniques, a moving window and an explicit vectorization of the equations are implemented, leading to 27% peak performance on one core at the SuperMUC (Phase 1). Apart from the code level performance engineering, the scientists optimized the model and the thermodynamic parameters. The description of the thermodynamic energies from Calphad databases are integrated in the phase-field model through fitting of paraboloids around the ternary eutectic point, enabling the use of less complex functions. By exploiting physical properties, e.g. the high diffusion rate of the temperature compared to the concentration, the researchers can describe the temperature evolution by using an analytic temperature gradient. Due to these optimizations, efficient and large-scale simulations of ternary eutectic directional solidification processes are possible.

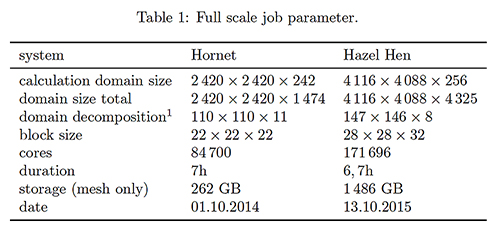

The good performance results of the highly optimized solver on all three German Tier-1 systems, associated in the Gauss Centre for Supercomputing (GCS), are shown in [6]. Table 1 summarizes the parameters of two large-scale simulations conducted on the entire Hazel Hen machine and the former Hornet system, both of HLRS Stuttgart.

To validate the simulation results, the KIT/HSKA collaborates with data analysis scientists at the Georgia Institute of Technology to quantitatively compare the simulations with the experimental micrographs from DLR and UAB, using principle component analysis based on two point correlations [4]. The simulation results are in good accordance with the experiments.

As the next steps, scale bridging microstructures such as eutectic colonies and dendritic-eutectic phase arrangements are to be considered, requiring even larger domains, better optimized code and more powerful high performance computers.

___________________________________________________________________________________

1 In the older code version, used for the Hornet simulation, a load balancing of the subdomains/blocks was applied. Therefore three layers of 110 × 110 cores are weighted twice such that only one block was calculated by a core, whereby the other cores calculated two blocks.

References

[1] A. Choudhury. Quantitative phase-field model for phase transformations in multi-component alloys (Schriftenreihe des Instituts für Angewandte Materialien, Karlsruher Institut für Technologie). KIT Scientific Publishing, 6 2013. ISBN 9783731500209.

[2] A. Choudhury, Michael Kellner, and Britta Nestler. A method for coupling the phase-field model based on a grand-potential formalism to thermodynamic databases. Current Opinion in Solid State and Materials Science, (0):–, 2015. ISSN 1359-0286. doi: dx.doi.org/10.1016/j.cossms.2015.03.003. URL http://www.sciencedirect.com/science/article/pii/S135902861500025X.

[3] Johannes Hötzer, Marcus Jainta, Philipp Steinmetz, Britta Nestler, Anne Dennstedt, Amber Genau, Martin Bauer, Harald Köstler, and Ulrich Rüde. Large scale phase-field simulations of directional ternary eutectic solidification. Acta Materialia, 93(0):194 – 204, 2015. ISSN 1359-6454. doi: 10.1016/j.actamat.2015.03.051. URL http://www.sciencedirect.com/science/article/pii/S135964541500227X.

[4] Philipp Steinmetz, Yuksel C. Yabansu, Johannes Hötzer, Marcus Jainta, Britta Nestler, and Surya R. Kalidindi. Analytics for microstructure datasets produced by phase-field models. Acta Materialia, 2015.

http://www.sciencedirect.com/science/article/pii/S1359645415007363

[5] Johannes Hötzer, Philipp Steinmetz, Marcus Jainta, Sebastian Schulz, Michael Kellner, Britta Nestler, Amber Genau, Anne Dennstedt, Martin Bauer, Harald Köstler, and Ulrich Rüde. Phase-field simulations of spiral growth during directional ternary eutectic solidification. Acta Materialia (submitted).

[6] M. Bauer, J. Hötzer, P. Steinmetz, M. Jainta, M. Berghoff, F. Schornbaum, C. Godenschwager, H. Köstler, B. Nestler, and U. Rüde. Massively parallel phase-field simulations for ternary eutectic directional solidification. The International Conference for High Performance Computing, Networking, Storage, and Analysis (SC15). http://arxiv.org/abs/1506.01684.

Scientific Team and Contact Information

Johannes Hötzer1,2 , Philipp Steinmetz1, Michael Kellner1, and Britta Nestler1,2

1Institute for Applied Materials (IAM), Karlsruhe Institute of Technology (KIT), Haid-und-Neu-Str. 7, 76131 Karlsruhe, Germany

2Institute of Materials and Processes, Karlsruhe University of Applied Sciences, Moltkestrasse 30, D 76133 Karlsruhe, Germany

Scientific contact:

Johannes Hötzer

Hochschule Karlsruhe - Technik und Wirtschaft, Institute of Materials and Processes

Karlsruher Institut für Technologie - Institut für Angewandte Materialien, Computational Materials Science (IAM-CMS)

Haid-und-Neu-Str. 7, D-76131 Karlsruhe/Germany

E-mail: johannes.hoetzer@kit.edu

E-mail: johannes.hoetzer@hs-karlsruhe.de

http://www.imp.hs-karlsruhe.de/

http://www.iam.kit.edu/zbs/index.php

http://www.youtube.com/user/IMPKarlsruhe