MATERIALS SCIENCE AND CHEMISTRY

Molecular Dynamics Simulations on Strengthening Caused by GP-Zones in Al-Cu Alloys

Principal Investigator:

Martin Hummel

Affiliation:

Institut für Materialprüfung, Werkstoffkunde und Festigkeitslehre (IMWF), Universität Stuttgart

Local Project ID:

SFB716B7

HPC Platform used:

Hermit of HLRS

Date published:

Aluminum alloys are widely used construction materials. A long tradition in metallurgy provides a lot of knowledge concerning the material behavior while different alloying surcharges are added or manufacturing processes are passed through. The strengthening in Aluminum-Copper alloys is based on different mechanisms, which are namely solid solution hardening, precipitate- and grain-boundary-strengthening. To investigate these empirical well known effects on atomistic length scale Molecular Dynamics (MD) simulations are indispensable.

The interaction between each atom is considered in these numerical calculations and since the configurations consist of up to 100 million particles the computational effort is very high. High performance facilities like the High Performance Computing Center Stuttgart are the only possibility to provide the necessary infrastructure. Suitable simulation software is the other basic necessity, which is given in this case by the software package IMD, which was specially developed at the University of Stuttgart for massive parallel computations on clusters.

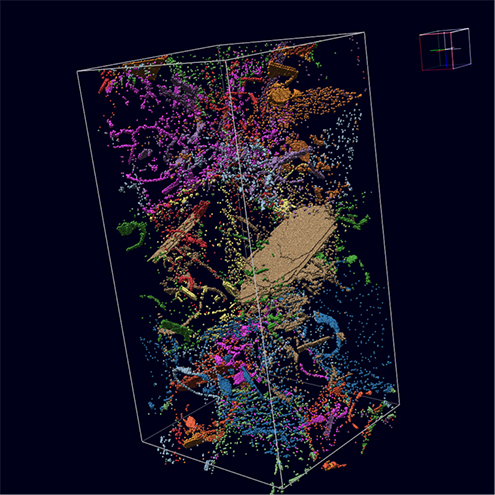

Tensile tests are performed to observe the formation, evolution, movement and interactions of dislocations with each other, grain boundaries and other defects. A high required stress for the dislocation formation was observed, yet it is about a factor of five lower compared to a single crystal. This is explained by the dislocation emission from the grain boundaries, which are defects in the otherwise perfect crystal (Figure 1).

Figure 1(a): An aluminum poly crystal during a simulated tensile test is shown, which consists of 26 million atoms in 20 grains. Atoms in fcc configuration are invisible, each color represents one grain. In the center a stacking fault is present, on the surrounding there are several dislocations as well as point defects. (A gif animation of this test is shown at the end of the report)

Copyright: Universität Stuttgart, IMWF

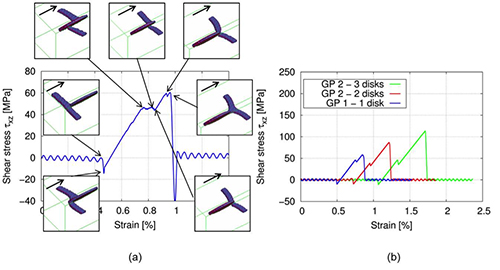

The critical resolved shear stress (CRSS) to overcome Guinier-Preston (GP) zones, monoatomic layers of copper within the aluminum matrix, was obtained by shear simulations (Figure 2). The GP 1 and GP 2 zones represent different ageing stages of the system and they result in higher required CRSS values to overcome the precipitates.

Figure 2: Different phases of cutting a GP-1-zone in the (001)-orientation by a dislocation (a). Transfer of the CRSS during the cutting of the GP-zone with a plurality of disks (b).

Copyright: Universität Stuttgart, IMWF

This work was part of the Collaborative Research Center (SFB) 716 financially supported by the DFG and carried out at the IMWF (Institute for Materials Testing, Materials Science and Strength of Materials; University of Stuttgart).

Figure 1(b): An aluminum poly crystal during a simulated tensile test is shown, which consists of 26 million atoms in 20 grains. Atoms in fcc configuration are invisible, each color represents one grain. In the center a stacking fault is present, on the surrounding there are several dislocations as well as point defects

Copyright: Universität Stuttgart, IMWF

Scientific Contact:

Martin Hummel

Universität Stuttgart, Institut für Materialprüfung, Werkstoffkunde und Festigkeitslehre (IMWF)

Pfaffenwaldring 32, D-70569 Stuttgart/Germany

e-mail: Martin.Hummel [at] imwf.uni-stuttgart.de