MATERIALS SCIENCE AND CHEMISTRY

Piezoelectric Hafnia and Zirconia

Principal Investigator:

Alfred Kersch

Affiliation:

Department of Applied Sciences and Mechatronics, Munich University of Applied Sciences (Germany)

Local Project ID:

pr27su

HPC Platform used:

SuperMUC and SuperMUC-NG of LRZ

Date published:

Introduction

Materials possessing piezoelectric characteristics generate an electric signal as a response to mechanical stress, and mechanical strain if an electric field is applied.

Such materials are indispensable for actuators, transducers and sensors. Piezoelectric devices can be found in the phone and digital cameras, microscope lenses, fuel injectors, micro-pumps, inkjet printers, medical instruments.

The most prominent piezoelectric materials are based on the perovskite crystal structure but may lose their properties in nano-scaled devices.

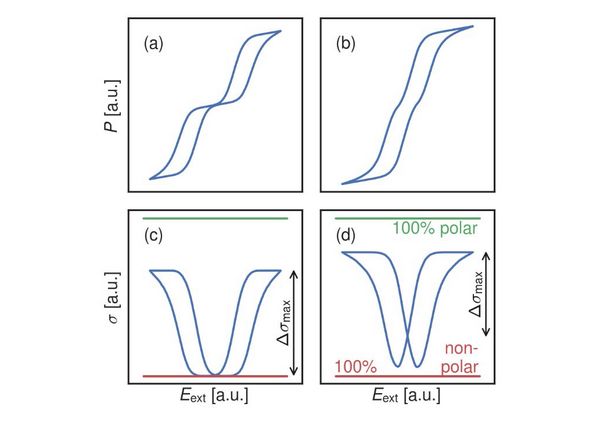

Recently, a ferroelectric phase was stabilized in HfO2 and ZrO2 based thin films which persisted down to a few nanometer thicknesses [Bö]. In contrast to all prominent piezoelectrics, this material is based on the fluorite crystal structure. The scope of the current study is to reveal the possible piezoelectric effects. All ferroelectric films are known to be piezoelectric, but very large piezoelectric constants are found in antiferroelectric materials where the electric field induces a phase transition from a paraelectric to a ferroelectric phase. The large mechanical strain derives then from the volume difference of the participating phases. The field-induced strain mechanism is known to be realized in recently developed lead-free ceramic materials such as barium titanate, BaTiO3 (BT), bismuth sodium titanate, Bi0.5Na0.5TiO3 (BNT), and potassium-sodium niobate, K0.5Na0.5NbO3 (KNN) [Jo].

Figure 1: (a) and (b) show the field-induced polarization in differently conditioned antiferroelectric materials. For small electric field, the material is predominantly paraelectric, for larger fields, the polarization increases rapidly in relation to the paraelectric to ferroelectric phase transition. (c) and (d) show the field-induced strain curves where the slope measures the effective piezoelectric coefficient. (Reprinted (adapted) with permission from ACS Applied Materials & Interfaces [1]. Copyright 2020 American Chemical Society.)

Methods

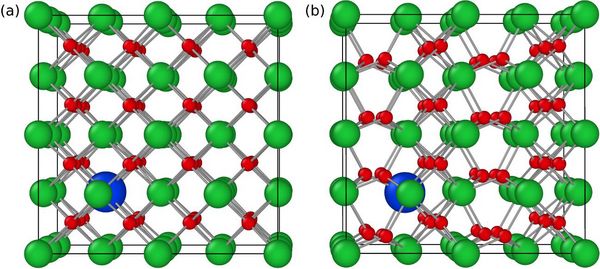

To bring the material into the antiferroelectric state, extrinsic doping can be used [2]. To explore the potential of hafnia and zirconia as piezoelectric and to find the material with the largest strain, a dopant screening study was done. 58 possible dopants were chosen as a dopant in HfO2 and ZrO2 in a concentration of 3.125% and 6.25%. Because the dopant can be inserted in several positions, a large number of doped configurations was built to find the energetically most favourable.

Finally, because the favoured crystal phase is uncertain under these conditions, the structures were considered for all relevant, competing crystal phases, among them the paraelectric and ferroelectric phase in focus.

The calculation of the energy and crystal volume of thousands of structures was then done ab initio with density functional theory calculations. Such calculations require massive parallel computer modelling.

Results

The calculations revealed at first the most favourable dopant configuration and the energetic order of the possible crystal phases. The achieved configuration furthermore depends on the oxygen chemical potential, which is controlled with the production process. The achieved results, therefore, include the recommended production condition.

Then the energetic order of the crystal phases was analyzed. In the case of paraelectric and ferroelectric crystal energies with a certain difference, which is suitable to allow a field-induced phase transition, a potential material with the desired antiferroelectric properties was recognized.

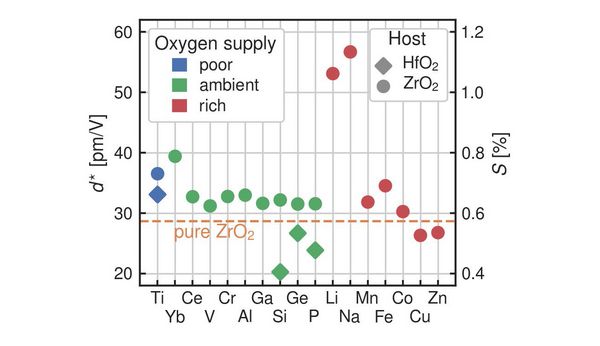

Last, the volume difference between the paraelectric and ferroelectric phase was searched and the according effective piezoelectric coefficient calculated. The final result in Figure 3 gives calculated coefficients for differently doped materials, including a specification of the required chemical potential for the production process.

In Si-doped HfO2 thin films, experimentally a piezoelectric coefficient of 20 pm/V was found, which fits well to the predictions. The value compares with 4 pm/V in AlN thin films, the standard material used for mobile communication transducers.

The screening reveals that generally, ZrO2 based material show larger coefficients then HfO2 based material. Appropriately doped, ZrO2 may have a much larger piezoelectric coefficient than for the so far experimentally found materials. The calculated results may serve as a guideline to optimize the piezoelectric coefficient in hafnia and zirconia.

Publications

[1] M. Falkowski, A. Kersch, "Optimizing the Piezoelectric Strain in ZrO2 - and HfO2 -Based Incipient Ferroelectrics for Thin-Film Applications: An Ab Initio Dopant Screening Study", ACS Applied Materials & Interfaces (2020), 12:29, 32915–32924, https://doi.org/10.1021/acsami.0c08310

[2] M. Falkowski, Ch. Kuenneth, R. Materlik and A. Kersch, "Unexpectedly Large Energy Variations from Dopant Interactions in Ferroelectric HfO2 from High Throughput ab initio Calculations", npj Computational Materials (2018) 4:60, https://doi.org/10.1038/s41524-018-0133-4

Additional References

[Bö] Böscke, T. S.; Müller, J.; Bräuhaus, D.; Schröder, U.; Böttger, U. Ferroelectricity in Hafnium Oxide Thin Films. Appl. Phys. Lett. 2011, 99, 102903

[Jo] W. Jo, R. Dittmer, M. Acosta, J. Zang, C. Groh, E. Sapper, K. Wang, and J. Rödel, Journal of Electroceramics 29, 71 (2012)

Researchers

Max Falkowski, Alfred Kersch (Department of Applied Sciences and Mechatronics, Munich University of Applied Sciences)

Scientific Contact

Prof. Dr. Alfred Kersch

Department of Applied Sciences and Mechatronics

Munich University of Applied Sciences

Lothstr. 34, D-80335 Munich (Germany)

e-mail: akersch [@] hm.edu

Local project ID: pr27su

December 2021