ENGINEERING AND CFD

Highly-Resolved Numerical Simulation of Combustion in Energy Conversion Processes

Principal Investigator:

Hening Bockhorn

Affiliation:

Engler-Bunte-Institute/Combustion Technology, Karlruhe Institute of Technology (Germany)

Local Project ID:

Cnoise

HPC Platform used:

Hazel Hen of HLRS

Date published:

Despite a rapid growth in the production of renewable energy and engineering improvements, British Petroleum predicts that still 80% of the global energy will be supplied by burning fossil fuels until 2035. Moreover, combustion plays an important part of most overall energy conversion systems, especially when using renewable fuels in energy storage concepts. Therefore, combustion remains a key technology in most current and future overall energy conversion systems. However, combustion is connected with serious environmental problems. One of these problems is the emission of combustion noise from combustion devices, particularly under turbulent flow conditions.

Actual research conducted in the Section of Combustion Technology of the Engler-Bunte-Institute at Karlsruhe Institute of Technology (KIT) (principal investigators: Dr. Feichi Zhang, MSc. Thorsten Zirwes, Dr. Peter Habisreuther, Prof. Dr. Henning Bockhorn, and Prof. Dr. Dimosthenis Trimis) is directed towards this problem. The research has been founded by the German Research Council (DFG) for the period 2012 to 2017 with a group of researchers from different institutions, among them, TU Berlin (Prof. Dr.-Ing. Paschereit), RWTH Aachen (Prof. Dr.-Ing. Schröder), TU Darmstadt (Prof. Dr.-Ing. Janicka) and KIT Karlsruhe (Prof. Dr.-Ing. Bockhorn). The joint project covers extensive experimental and numerical studies of a novel generic burner system, with the overriding objective to gain a deeper understanding of the generation mechanism of noise emitted by turbulent combustion process.

As a pre-requisite in this case, the flame-turbulence interaction, which is the main cause of combustion noise, has to be first resolved in detail by highly-resolved numerical simulation. This represents the major and most challenging task of the current project. The noise emission due to unsteady combustion is then evaluated as a byproduct.

The numerical approach reproduces the interactions between underlying multi-physical mechanisms, considering thermodynamics, fluid dynamics, chemical kinetics, and acoustics. It solves numerically a large number of highly non-linear partial differential equations, including mass balance equations of up to hundreds of chemical species and thousands of chemical reactions. Several hundred millions or billions of finite volumes are commonly used to conduct the virtual computational domain and to resolve the smallest length scale of the chemically reacting flow, which is typically in the range of 10 micrometers. Therefore, such type of simulation for combustion processes is extremely demanding of computing time and can only be realized with help of peta-scale supercomputers. The results of the detailed simulations of turbulent combustion are able to partially replace elaborate experiments and can be used to develop subordinate modeling concepts, which can be incorporated in practical applications.

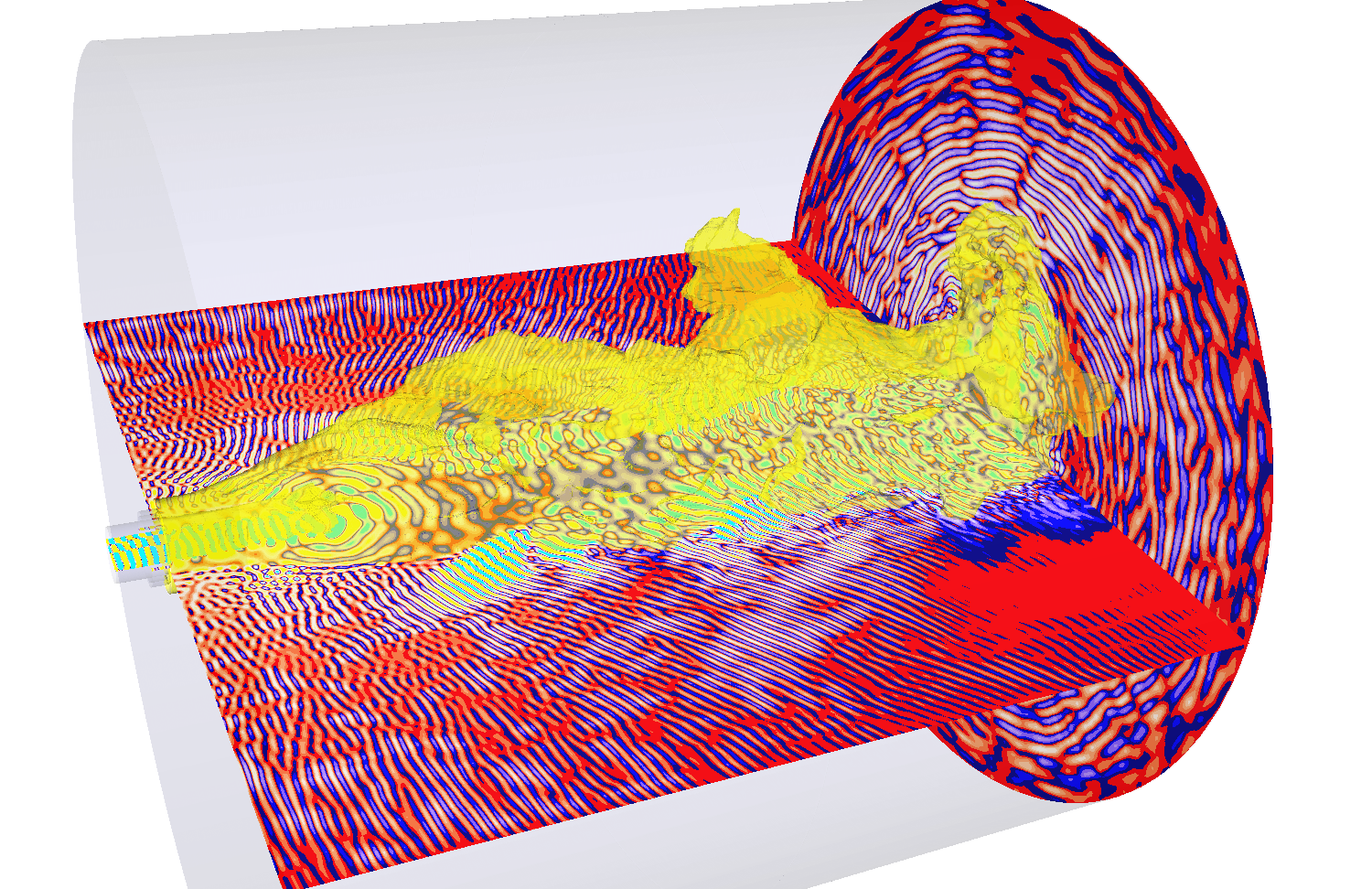

In the project, an efficient solver with highly optimized algorithms for computing chemical reactions in the widespread open-source code OpenFOAM [1-3] has been developed. It has then been used to simulate different flame configurations [4-7]. Fig.1 shows simulation results of a turbulent flame operated with methane/air mixture, illustrating turbulent flow structures generated during mixing of fuel jet and coflow air in the shear layer. Fig.2 visualizes outwardly propagating acoustic wave fronts due to turbulent combustion by contours of acoustic pressure, which are sensed as combustion noise emitted by the flame. Both simulations have been carried out on the Hazel-Hen platform at the High-Performance Computing Center HLRS in Stuttgart, using up to 20,000 CPU cores and consuming in total 20 million CPU hours. We gratefully acknowledge the support by GCS and HLRS for providing the large amount computing resources.

esearch Team:

Henning Bockhorn (PI), Peter Habisreuther, Dimosthenis Trimis, Feichi Zhang, Thorsten Zirwes, Karlsruhe Institute of Technology (Germany)

References:

1. T. Zirwes, F. Zhang, J.A. Denev, P. Habisreuther, H. Bockhorn, D. Trimis. Improved Vectorization for Efficient Chemistry Computations in OpenFOAM for Large Scale Combustion Simulations. Accepted for publication In High Performance Computing in Science and Engineering '18, Nagel W., Kröner D., Resch M. (ed.), Springer International Publishing, 2019.

2. T. Zirwes, F. Zhang, J.A. Denev, P. Habisreuther, H. Bockhorn. Automated Code Generation for Maximizing Performance of Detailed Chemistry Calculations in OpenFOAM. In High Performance Computing in Science and Engineering '17, Nagel W., Kröner D., Resch M. (ed.), Springer International Publishing, 189-204, 2018.

3. F. Zhang, H. Bonart, T. Zirwes, P. Habisreuther, H. Bockhorn, N. Zarzalis. Direct Numerical Simulation of Chemically Reacting Flows with the Public Domain Code OpenFOAM. In High Performance Computing in Science and Engineering '14, Nagel, Wolfgang E. and Kröner, Dietmar H. and Resch, Michael M. (ed.), Springer International Publishing, 221-236, 2015.

4. T. Zirwes, F. Zhang, T. Häber, H. Bockhorn. Ignition of combustible mixtures by hot particles at varying relative speeds. Combus. Sci. Technol., 2018.

5. T. Häber, T. Zirwes, D. Roth, F. Zhang, H. Bockhorn, U. Maas. Numerical Simulation of the Ignition of Fuel/Air Gas Mixtures around Small Hot Particles. Z. Phys. Chem. 231(10): 1625–1654, 2017.

6. F. Zhang, T. Zirwes, P. Habisreuther, H. Bockhorn. Effect of unsteady stretching on the flame local dynamics. Combustion and Flame, 175, 170-179, 2017.

7. F. Zhang, T. Zirwes, H. Nawroth, P. Habisreuther, H. Bockhorn, C.O. Paschereit. Combustion generated noise: an environment related issue for future combustion systems. Energy Technol., 5, 1045-1054, 2017.

Scientific Contact:

Dr.-Ing. Feichi Zhang

Karlsruhe Institute of Technology (KIT)

Engler-Bunte-Institute—Division of Combustion Technology

Engler-Bunte-Ring 1,76131 Karlsruhe, Germany

e-mail: feichi.zhang [at] kit.edu

http://vbt.ebi.kit.edu/index.pl/en/Haupt_Menu_Institut_M01/html/uebersicht.html

December 2018

Project ID: Cnoise