ENGINEERING AND CFD

Numerical Computation of Combustion Generated Noise with Direct Numerical Simulation

Principal Investigator:

Feichi Zhang

Affiliation:

Karlsruhe Institute of Technology

Local Project ID:

Cnoise

HPC Platform used:

Hermit of HLRS

Date published:

The project has been founded by the German Research Council (DFG) through the Research Unit ”Combustion Noise”, which has been established by a group of different institutions, among others, TU Berlin (Prof. Dr. -Ing. Paschereit), RWTH Aachen (Prof. Dr.-Ing. Schröder), TU Darmstadt (Prof. Dr.-Ing. Janicka) and KIT Karlsruhe (Prof. Dr. -Ing. Bockhorn). The joint project covers experimental and numerical investigations of a generic burner system with natural gas as fuel, which has been measured at the Institute of Fluid Dynamics and Technical Acoustics in TU Berlin.

The most challenging work of the current project is to perform three-dimensional direct numerical simulations (DNS) for the considered burner configuration. The DNS approach numerically calculates the governing system of N + 5 non-linearly coupled partial differential equations (PDE), where the number of reacting species N could be more than 50 for methane/air combustion. In addition, the whole range of length scales, i.e. until the smallest one, has to be resolved by the DNS, which leads to a large number of grid cells, e.g. more than 100 million. Hence, on the one hand, DNS represents the most accurate method and on the other hand it is also the most computing-resource demanding method among the methodologies used for simulation of turbulent combustion, which can only be accomplished with help of tetra-/petascale supercomputers.

The DNS of simple turbulent combustion cases enables a deeper understanding of the interplay between the underlying flow, chemistry and transport processes, which plays a significant role for the efficiency of the combustion system. The fine-grained results may validate and improve subordinate modelling concepts and complement measurement, or even partially replace elaborate experiments, which can then be incorporated in engineering modelling applications. Consequently, the time scale and cost required for development of future combustion device may be reduced.

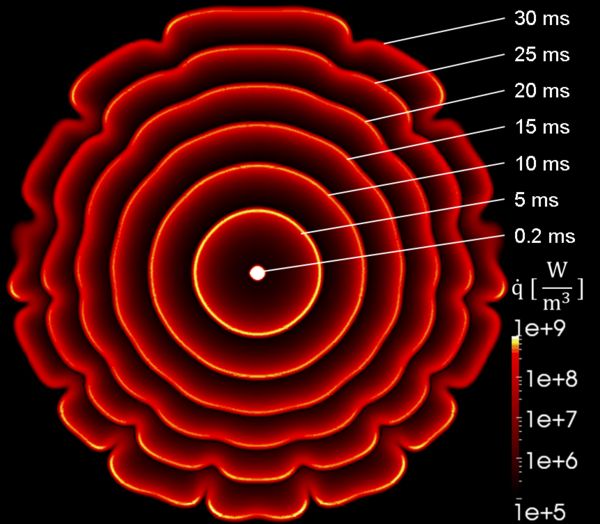

Figure 1: Three-dimensional DNS of a propagating spherical flame in an explosion vessel by use of a computational grid with 144 million cells: contours of the heat release rate for a time series indicating temporal evolution of the flame front in the explosion vessel.

Copyright: © Karlsruhe Institute of Technology (KIT), Engler-Bunte-Institut, Lehrstuhl für Verbrennungstechnik (EBI vbt)

Figure 2: Three-dimensional DNS of a propagating spherical flame in an explosion vessel by use of a computational grid with 144 million cells: volume rendering of the temperature field with different colormaps.

Copyright: © Karlsruhe Institute of Technology (KIT), Engler-Bunte-Institut, Lehrstuhl für Verbrennungstechnik (EBI vbt)

Figure 3: Three-dimensional DNS of a turbulent jet flame on a computational grid with 111 million cells: volume rendering of the heat release rate (left) and the temperature (right).

Copyright: © Karlsruhe Institute of Technology (KIT), Engler-Bunte-Institut, Lehrstuhl für Verbrennungstechnik (EBI vbt)

We gratefully acknowledge HLRS’ support for providing the large amount of computing time, which makes the research pro ject possible.

Scientific Contact:

Dr.-Ing. F. Zhang

Karlsruhe Institute of Technology (KIT) Engler-Bunte-Institute

Division of Combustion Technology

Engler-Bunte-Ring 1, D-76131 Karlsruhe

e-mail: feichi.zhang@kit.edu