ENVIRONMENT AND ENERGY

Large Eddy Simulation of Large-Scale Coal and Biomass Combustion

Principal Investigator:

Andreas Kempf

Affiliation:

Institut für Verbrennung und Gasdynamik, Lehrstuhl Fluiddynamik, Universität Duisburg-Essen (Germany)

Local Project ID:

pr84mu

HPC Platform used:

SuperMUC of LRZ

Date published:

Scientists of the University of Duisburg-Essen pushed further the state of the art by simulating large-scale coal and biomass flames in furnaces that have been studied in detail experimentally – the Instituto Superior Técnico and the Brigham Young University furnace. Within this project, the largest large eddy simulation (LES) of coal combustion ever to be computed provided high-resolution scalar profiles within the furnace, which allowed investigating the conditions that coal particles are subjected to in these applications and to compute particle combustion histories. LES is able to provide insights to the phenomena occurring in this type of application that are currently not available through experimental means.

Coal will continue to be the dominant fuel for electricity production in the foreseeable future, owing to its abundance and the ongoing construction of new power plants that will run for decades. European efforts to establish a green economy have promoted the growth of biomass co-firing and also pure biomass combustion. Biomass is normally carbon neutral and has the potential to reduce CO2, SOx and NOx emissions when co-fired with coal. Coal and biomass combustion follows many steps that may occur sequentially or simultaneously in a turbulent environment and includes a complex degree of non-linear interactions. The understanding of the involved processes is fundamental to the development of CFD tools that can assist with the development of efficient, low polluting coal and biomass burners.

A comprehensive understanding of the processes involved in pulverized coal and biomass combustion (PCBC) can only be obtained by using advanced techniques for simulating turbulent flows, such as the large eddy simulation (LES). The LES relies on solving the flow on a grid that is just fine enough to resolve most of the flow scales while modeling only the small scale flow features. In the context of large-scale PCBC simulations, this is highly required since only the LES can resolve most of the interaction between turbulence and physical and chemical processes occurring in pulverized coal and biomass combustion with realizable computational effort.

Such types of applications possess a broad range of scales, owing to a very high ratio between the furnace diameter and the injection slot diameter easily of 2 orders of magnitude. This requires a long initialization period, followed by a long period of statistics collection. Coal and biomass particles require up to a few seconds to reach full burnout while inside the furnace, therefore simulations have to cover up to 10 seconds physical time, which is one order of magnitude higher of typical LES.

Figure 1: View of selected Eulerian fields from a high-resolution simulation of the IST furnace. (a) Axial view of temperature [K]; (b) Axial view of O2 mass fraction [-]; (c) Transversal view of viscosity ratio (μt/μl) [-]; (d) Transversal view of O2 mass fraction [-]. Subfigures (a) and (b) show the near burner only, in a window covering only one third of the computational domain in both axial and radial direction. Subfigures (c) and (d) correspond to a quarter of the transversal circular plane corresponding to the middle section of the simulated domain.

Copyright: Institute for Combustion and Gas Dynamics, Universität Duisburg-EssenIn the framework of the 7th PRACE regular access project, leveraging the computing capacities of LRZ HPC system SuperMUC, the team led by Prof. Andres Kempf from the University of Duisburg-Essen pushed further the state of the art by simulating large-scale coal and biomass flames in furnaces that have been studied in detail experimentally – the IST (Instituto Superior Técnico) and the BYU (the Brigham Young University) furnace. Within this project, the largest LES of coal combustion ever to be computed provided high-resolution scalar profiles within the furnace, which allowed investigating the conditions that coal particles are subjected to in these applications and to compute particle combustion histories.

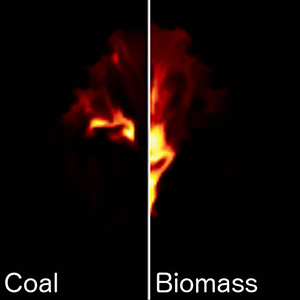

LES is able to provide insights to the phenomena occurring in this type of application that are currently not available through experimental means. Furthermore, simulations of coal and biomass co-firing provide new insight on the how the coal and biomass particles behave comparatively when exposed to the same conditions, which again is not possible to obtain experimentally. The project continues now under a 12th Call for Large-Scale Project, where more advanced coal and biomass combustion models are being developed and implemented.

So far, this projected resulted in one journal publication on the Proceedings of the Combustion Institute, one the highest impact journals in combustion, 4 communications in international conferences, and media contributions for the PRACE booth at the ISC14 and SC14. Given the substantial amount of data produced during the first year of the project, further

journal publications are still in preparation.

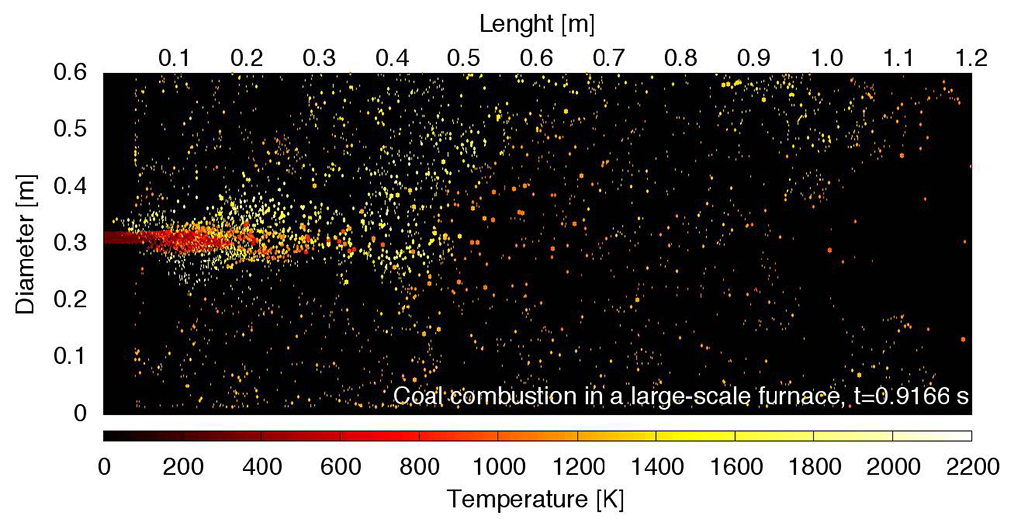

Figure 2: Particle instantaneous location within the IST furnace at the physical runtime of t = 0.9137 s, at the end of the initialization period. Particles are scale to their actual size and colored by temperature.

Copyright: Institute for Combustion and Gas Dynamics, Universität Duisburg-Essen

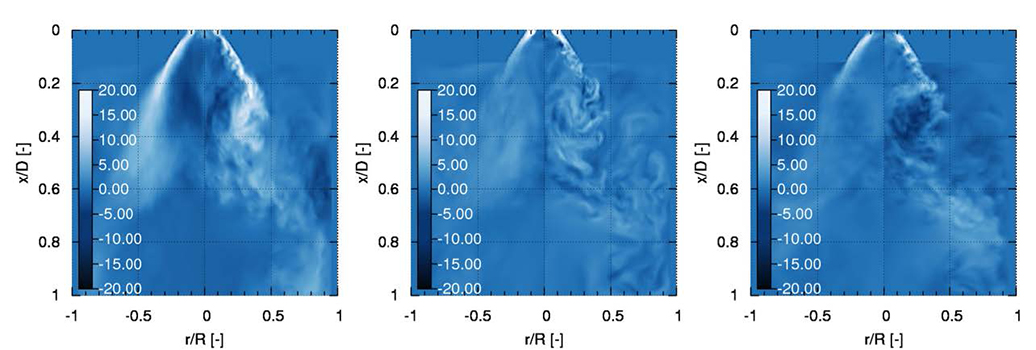

Contours of the three velocity components in the BYU furnace. From left to right: axial, tangential and radial velocity. Mean on the left and instantaneous on the right of each plot.

Copyright: Institute for Combustion and Gas Dynamics, Universität Duisburg-Essen

Figure 4: Contours of the three velocity components in the BYU furnace. From left to right: axial, tangential and radial velocity. Mean on the left and instantaneous on the right of each plot.

Copyright: Institute for Combustion and Gas Dynamics, Universität Duisburg-EssenScientific contact:

Prof. Dr.-Ing. Andreas Kempf

Institut für Verbrennung und Gasdynamik, Lehrstuhl Fluiddynamik, Universität Duisburg-Essen

Carl-Benz-Str. 199, D-47057 Duisburg/Germany

e-mail: andreas.kempf @ uni-due.de