MATERIALS SCIENCE AND CHEMISTRY

Scientists Compute Expansion of the Compound Catalog

Principal Investigator:

Jadran Vrabec

Affiliation:

Thermodynamik und Energietechnik, Universität Paderborn (Germany)

Local Project ID:

MMHBF

HPC Platform used:

Hermit of HLRS

Date published:

Chemical processes help create everything from plastic containers to antifreeze to fertilizers. Many products and materials humanity uses daily come from a field only around 100 years old. Through those hundred years, chemical companies pushing the boundaries of science have often had to play a dangerous game of trial and error while experimenting with compounds.

In some cases, companies find a new synthetic waterproof material or liquid coolant, but many of the associated experiments have also ended with hazardous situations and noxious clouds. Researchers using the University of Stuttgart’s HLRS (High Performance Computing Center) supercomputing resources aim to help not only make the fundamentals of chemical processes safer and more predictable, but also as energy efficient as possible.

“We have many compounds that are important to our daily lives, and we only have a small fraction of experimental data,” says Dr. Jadran Vrabec, professor of thermodynamics and energy technology at the University of Paderborn. Vrabec works with academia and industry to determine the behavior of various pure compounds and mixtures. Researchers have problems creating experiments to define compound behavior, as many are too costly, time consuming, or dangerous. “We only have a profound understanding of about 50–60 pure compounds, and when you start mixing things, the number of options just gets out of hand,” Vrabec says.

In addition to options, the results of mixing and separating chemical compounds can get out of hand without precision. Explosions are just one of the many risks for the chemical industry. Due to these risks, many companies stick to decades-old methods for producing compounds and are hesitant to try and modernize the process for fear of creating a volatile situation. As a result, many of these processes are less efficient than they could be. The Haber-Bosch Process, for example, synthesizes ammonia from nitrogen and hydrogen to help create the world’s fertilizer supply. Its production eats away one percent of the world’s entire energy supply per year alone. Thermal separation processes in general are estimated to consume five percent of the entire world’s energy supply per year.

By using supercomputers, Vrabec and his colleagues gain insight into how altering chemical process conditions may improve energy efficiency, reduce the amount of unwanted side-product material, or how changing the actual physical process may improve separating compounds. “You want substances A and B to produce C, but you never completely get C, as you will always have some sort of mixture,” says Vrabec. Understanding the phase behavior, or the detailed properties of compounds in various states, is essential to for the chemical industry to make serious strides in efficiency.

These simulations employ supercomputer Hermit installed at HLRS, one of the three member centers of the German Gauss Centre for Supercomputing. Hermit is a Cray XE6 capable of more than one petaflop, or one thousand trillion calculations per second, of computing power. Hermit has 113,664 processing cores housed in 3552 dual-socket nodes with AMD Interlagos processors.

Predicting properties

Supercomputers are only as good as the algorithms used on them for simulations. To take advantage of a petaflop machine like Hermit, researchers must develop codes capable of using large amounts of the many processing cores available. As supercomputing technology gets faster, the demand on scalable algorithms and codes only grows. Many of these codes are developed in academia, only to be further developed and used by industry as commercial technology improves.

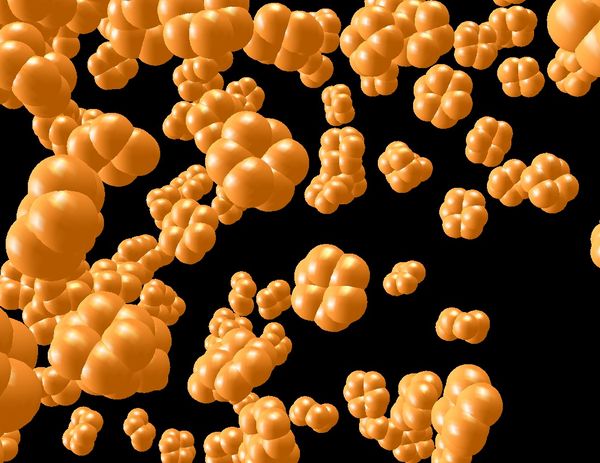

The ms2 code, one of the premier codes for thermodynamic simulations, was developed by Vrabec and his colleagues to serve this purpose. Scientists can use the code in small-scale simulation on personal computers, but it is also capable of using modern supercomputers such as HLRS’s Hermit to solve major problems facing the chemical industry. The code tackles one of the most difficult problems for researchers to solve with experiments—the phase behavior and the thermodynamic behavior of fluids in general. Vrabec explains that for any compound there are liquid and gaseous phases, and during chemical processes, knowing their properties is essential for safety and efficiency. “Take water as an example,” says Vrabec. “If you choose to boil water at a different pressure, the temperature will also change.” This process is exponentially more complicated with mixtures, and for large-scale chemical production, a comprehensive experimental approach is far too costly.

Computing-intensive research often requires collaboration from scientists from various institutions and organizations. For example, Vrabec and his collaborators work with German chemical conglomerate BASF SE to help simulate some of the many chemicals the company produces. Like many German chemical industry companies, BASF has a long track record of plant safety, but improving efficiency drives the company’s collaboration in simulation-based research. One of the team’s primary goals was to define the compound ethylene oxide’s interactions with water, and to more precisely predict its properties at the vapor-liquid equilibrium. At room temperature, ethylene oxide is a flammable, carcinogenic substance that has mutagenic properties, making computation an essential tool for researchers to better understand the substance and streamline production. Despite ethylene oxide’s volatile properties, the compound serves as a building block for drug manufacturing, antifreeze, polyester, detergents, and various polymers.

In 1960, the chemical compound hydrazine and its derivatives, a family of compounds used as propellants for satellites and rockets, but also has applications in plastic manufacturing and pesticide production, were the cause of a disaster in the Soviet Union. An explosion killed 74 people and fatally exposed 48 more to toxic chemicals. Swiss-based company Lonza Ltd has been safely conducting industrial-scale chemical processes with hydrazine and its derivatives for several decades, but to improve safety and efficiency in their hydrazine production, the company has employed supercomputing to help understand hydrazine’s properties in greater detail. Lonza and Vrabec’s research team were able to match simulation data with the limited amount of experimental data available, ultimately expanding knowledge of the compound’s properties in various states.

Research collaborations on German supercomputing resources do not end at German or European borders, though. Due to the relatively small group of researchers studying thermodynamics computationally, international collaboration is a key aspect of moving the field forward. Vrabec works with an international consortium of researchers at National Taiwan University, the University of Kaiserslautern, and Cleveland State University in mapping the properties of gaseous cyclohexane, which, in combination with its derivatives cyclohexanol and cyclohexanone, is used in nylon production. Separating compounds that are so closely related proves difficult, and as a result, scientists working on this compound are moving closer themselves. Vrabec is hosting post-doctoral research from Taiwan University to improve the predictive method for cyclohexane and its derivatives. If you want more information about this research, contact Jadran Vrabec at jadran.vrabec@uni-paderborn.de or Dr. Heinz Pöhlmann at poehlmann@hlrs.de.

(Author: Eric Gedenk)

HLRS Project ID: MMHBF

July 2013